Room Sensor for CO₂, Temperature and Relative Humidity

CDS201

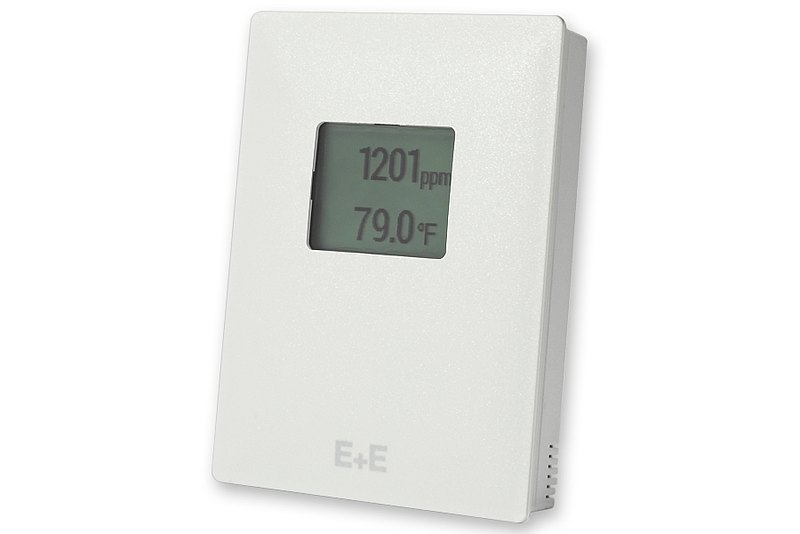

The CDS201 is optimised for demand controlled ventilation and building automation in residential and commercial applications. The versatile room sensor combines CO2, temperature (T) and relative humidity (RH) measurement in one device with modern design and state-of-the-art technology. The elegant enclosure is available in two sizes (EU and US format) and features an optional display.

Outstanding Measurement Performance

The CO2 measurement of the CDS201 relies on the pollution-resistant E+E dual wavelength NDIR technology. This measuring principle automatically compensates for ageing effects and ensures excellent long-term stability. The multiple point CO2 and temperature adjustment procedure leads to excellent CO2 measurement accuracy over the entire temperature working range.

The E+E proprietary sensor coating protects the RH/T sensing element from contamination and corrosive deposits. This improves the measuring performance and service life of the sensing element in dusty or dirty environments.

Outputs and Digital Interface

The CDS201 room sensor features analogue outputs or RS485 interface with Modbus RTU or BACnet MS/TP protocol. In the digital version, the CDS201 also calculates the dew point temperature (Td). The measured values can also be read locally on the optional graphic display.

The version with RS485 interface can be set up and configured via PC with the free PCS10 Product Configuration Software and an optional configuration adapter.

Installation-friendly Enclosure

The enclosure of the CDS201 facilitates fast and thus cost-saving installation. The back cover with the push-in spring terminals can be mounted and wired without the front cover. This means that the electronics, which are accommodated in the front cover, are not exposed to construction site pollution. Before commissioning, the active part can be simply snapped onto the back cover. Besides, the electronics part can be replaced without tools within seconds.

Typical Applications

- Demand controlled ventilation

- Heating, ventilation and air conditioning

- Building automation

Key Features

- CO2, T, RH measurement with a single device

- Calculation of dew point temperature Td (CDS201 with RS485)

- Pollution-resistant CO2 measuring principle

- RH/T sensing element protected by E+E proprietary coating

- High accuracy due to multiple point CO2 and T adjustment

- Modbus RTU, BACnet MS/TP or analogue outputs

- Large graphic display (optional)

- Snap-on enclosure for time-saving installation

- EU and US enclosure format

- Easy configuration

Technical data

- Measuring range - CO₂

- 0...2 000 ppm

0...5 000 ppm - Accuracy - CO₂

- < ±(60 ppm +2 % of measured value)

< ±(60 ppm +3 % of measured value) - Measuring range - Humidity

- 0...100 % RH, non-condensing

- Accuracy - Humidity

- ±(2.8 + 0.003 * mv) % RH (at 0...80 % RH)

±4.1 % RH (at >80...100 %RH) - Measuring range - Temperature

- -30...+60 °C (-22...+140 °F)

- Accuracy - Temperature

- ±0.35 °C (±0.63 °F), voltage output / RS485

±0.7 °C (±1.26 °F), current output - Output analogue

- 0-10 V or 4-20 mA

- Output digital

- RS485 (Modbus RTU or BACnet MS/TP)

- Power supply

- 15-35 V DC or 24 V AC ±20 %

Related products

Downloads CDS201

FAQ

Transmitter with "two-wire" technology receive the power from the process, and the signal is carried on return wire (closed current loop). With "three-wires" technology the power supply is separate from current output: 2 wires are the power supply and the third carries the signal.