Flow Sensor for Compressed Air and Gases

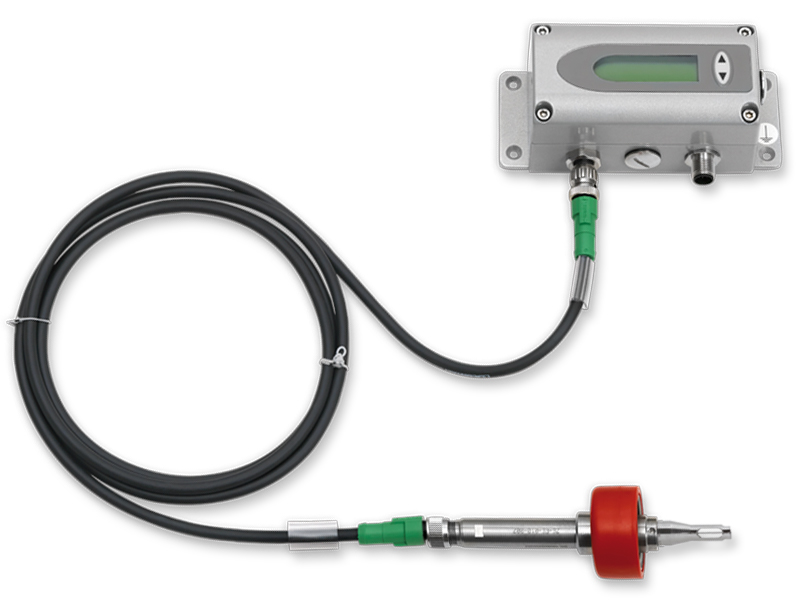

EE771

The EE771 is a thermal flow sensor for compressed air and gases. Irrespective of pressure and temperature, the EE771 flow meter registers mass flow, volumetric flow or standard flow.

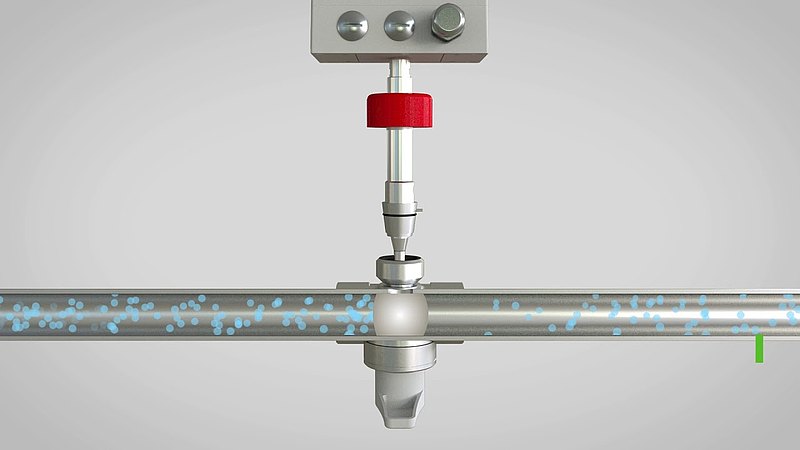

The flow sensor can measure the consumption of compressed air, nitrogen, oxygen, CO₂, argon or other non-corrosive gases. The measurement ball valve permits easy installation and removal with only a short interruption of the flow.

EE771 flow sensor employs the well proven E+E hot-film sensor element with high immunity to contamination, which leads to outstanding long-term stability and accuracy even under harsh operating conditions.

With wide measuring range from 0.5 to 200 Nm/s (100...39370 SFPM) (1:400) and fast response time, one and the same flow meter model can be employed throughout the entire gas supply system. It records accurately even the smallest flow which represent an essential prerequisite for calculating consumption costs or for finding leaks.

Every E+E flow sensor undergoes a precise factory calibration procedure at a pressure of 7 bar (102 psi), the corresponding calibration certificate is included in the standard scope of supply.

The EE771 flow sensor is available with an additional MODBUS RTU or M-BUS (Meter-Bus) interface.

For the use of this service, prior consent to the processing of your data and in particular to the setting of cookies is necessary. You can consent to the processing and setting of cookies here. Without your consent, your data will not be processed in connection with this service and no cookies will be set. You can revoke your consent at any time. For more information on cookies and the processing of your data in connection with this content and a way to revoke your consent, please see our privacy policy.

Key Features

- Measurement ball valve for rapid installation and removal with only a short flow interruption

- Remote, interchangeable probe for easy mounting

- Pipe diameter DN15 - DN50 (1/2" - 2")

- Pressure range up to 16 bar (232 psi) PN16

- Wide measuring range up to 200 Nm/s (39370 SFPM)

- Bus interface for MODBUS RTU or M-BUS

Technical data

- Measured values

- standardized volumetric flow, mass flow, standardised flow, temperature, consumption

- Measuring range

- 0.5 - 200 Nm/s (100…39370 SFPM)

- Accuracy

- ±1.5 % of the measured value

- Pipe diameter

- DN15 up to DN50 (1/2" - 2")

- Outputs

- 0-10 V, 0/4-20 mA, Pulse, Switch, Modbus RTU or M-Bus

- Supply

- 18 - 30 V AC/DC