Humidity Measurement in Fuel Cells

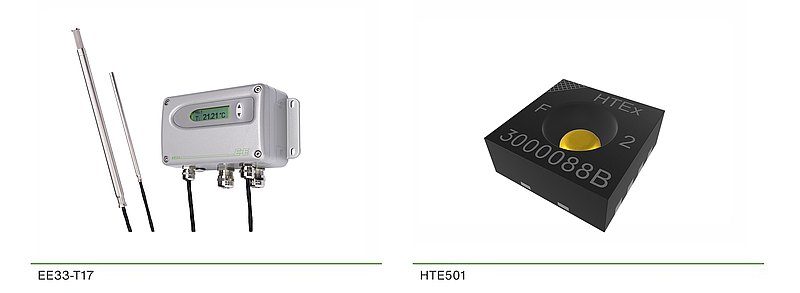

Climate protection is a megatrend in our society. The Paris Climate Agreement stipulates that we should be climate-neutral by 2050 to limit global warming to a maximum of +1.5 degrees. In order to achieve this ambitious goal, numerous measures have since been enacted with the European Green Deal. The fuel cell is a highly efficient and emission-free alternative to conventional methods of power generation. With the EE33-T17 humidity and temperature sensor and the HTE501 digital humidity and temperature sensing element, E+E Elektronik contributes to industrialize the technology and increase the efficiency of the aggregates.

Worldwide many regions – especially Europe, USA and Asia - have set ambitious targets for the expansion of alternative power generation systems. The targets include the promotion of CO2-free power plants as well as the promotion of clean energy. Thus, all signs are set on CO2 reduction. One possible alternative is the generation of energy via fuel cells.

Fuel cells convert chemical energy directly and without combustion into electrical energy and heat. The efficiency of a fuel cell essentially depends on the balance of water and temperature within the cell. This makes it more important to reliably monitor these factors over the long term. Not an easy task. The demanding environment and the long service life require highly sensitive measuring devices that can withstand permanent stress.

Condition Monitoring to Increase the Efficiency of Fuel Cells

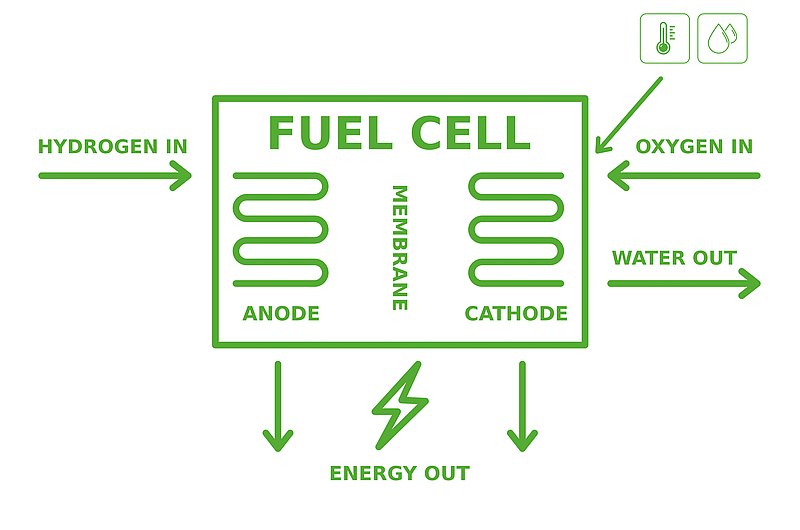

The functional principle of fuel cells is based on the conversion of the chemical reaction energy of a continuously supplied fuel (H2) and an oxidant (O2) into electrical energy. One of the most common types of fuel cell is the polymer electrolyte membrane (PEM) fuel cell. In a PEM, the supplied hydrogen reacts with the help of a catalyst at an anode and forms electrons and hydrogen nuclei (protons). The protons are transported via a correspondingly permeable membrane to the cathode, where they react with the oxygen supplied there to form water. The electrons are discharged via an external circuit and thus form the electric current. Fuel cells have a wide range of applications. In addition to stationary versions for decentralised energy generation, the vehicle industry in particular is one of the key sectors.

The efficiency of a fuel cell is limited by various factors. Some of the key mechanisms influencing these factors depend on the environmental conditions within the cell. If the temperature and humidity levels are not controlled accordingly, the catalyst and membrane will age more quickly. The cell loses power and may even be destroyed. The proton conductivity of the membrane and thus the performance and service life of a fuel cell increases proportionally with the water content of the polymer membrane. Therefore, this must be kept humid at all times. This is usually achieved by humidifying the reaction gases hydrogen and oxygen via a precise water pump. With the help of the humidity measurement in the fuel flow, this process can be continuously monitored and adjusted if necessary.

"Due to the European Green Deal and the decarbonisation movement, the hydrogen industry is experiencing an upswing. E+E Elektronik offers solutions for fuel cell drives from the measuring device to the highly accurate digital humidity element, which has been specially developed for demanding applications such as high humidity."

Carina Baumgartner, Key Account Manager Business Area "Elements & Modules"

The solution: The EE33-T17 and the HTE501 from E+E Elektronik

With the EE33-T17 humidity and temperature sensor for test benches and the HTE501 humidity and temperature sensing element for customised solutions, it is possible to perform highly accurate measurements with long-term stability even under harsh conditions. This is due in particular to the controlled heating of the sensing elements which, despite a highly humid environment, allows for precise measurement results. The sensor is used directly downstream the humidifier in the air or oxygen supply. This ensures that the membrane is continuously humidified sufficiently.

In addition, E+E Elektronik offers customised solutions for customer-specific applications. With the HTE501 as a sensing element, it is possible to develop and produce individual modules.

“Fuel cells are highly sensitive energy sources. To avoid damage - for example due to a malfunction of the humidifier - the EE33-T17 can be used, which measures long-term stable even under harsh environmental conditions such as high humidity and withstands the special chemical stresses. The EE33-T17 technology is used in countless test stands and ensures the highest efficiency and service life of the fuel cell."

Angelos Grantsanlis, Sales Manager E+E Elektronik Deutschland GmbH