Industrial Humidity and Temperature Sensor for Permanent High-Humidity and Polluted Environment

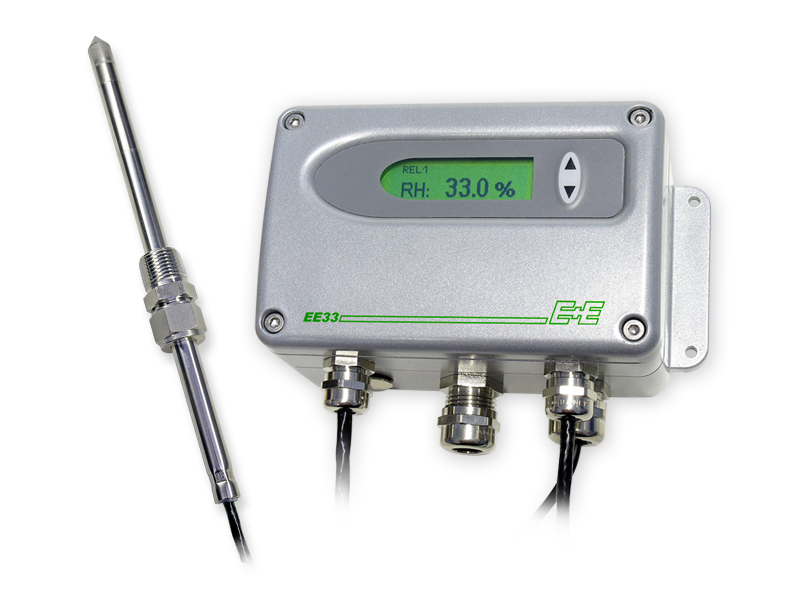

EE33

Important information:

Please note that the EE33 has been discontinued. Do not use/ specify EE33 for new projects, it is replaced by HTS801 humidity and temperature sensor.

EE33 is optimised for reliable humidity and temperature measurement in applications with temporary condensation, permanent high humidity or chemical exposure. Condensation on the monolithic humidity sensor and the filter cap is prevented by controlled heating of the sensor.

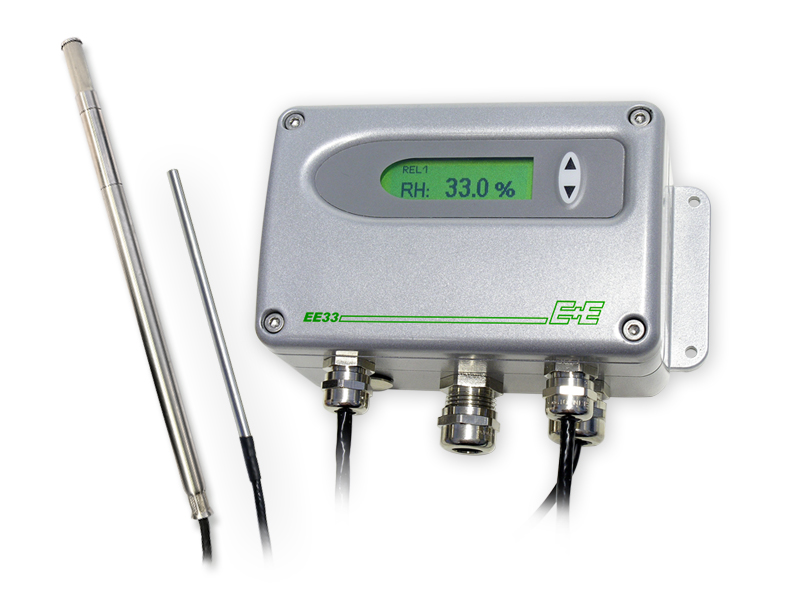

The measuring principle of EE33-T17 with separate humidity and temperature probes and dual heating enables precise continuous measurement even at permanent high humidity.

The remote probe can be employed up to 180°C (356°F) and the pressure tight version up to 100 bar. The three-part design of rugged enclosure in polycarbonate or aluminium allows easy mounting and replacement. The measurands are available on two analogue outputs and a serial interface.

An optional relay output can be used for alarms and process control. The proprietary coating protects the sensors and their leads against corrosive and electrically conductive pollution.

Typical applications

- Pharmaceutical and food industry

- Driers for ceramics, wood, concrete, polyester etc.

- Greenhouses, mushroom farms

- High-humidity storage rooms

- Climate, test and curing chambers

- Meteorology

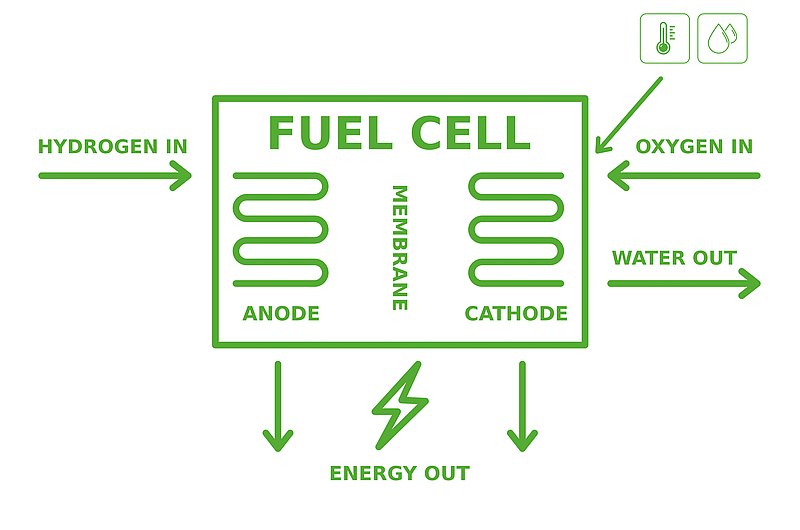

- Fuel cell test benches

Humidity Monitoring for Efficient Fuel Cells

Fuel cell technology is an environmentally friendly, emission-free alternative to conventional methods of generating electricity. Balancing the humidity and temperature inside the cell is crucial to the performance and lifetime of polymer electrolyte membrane (PEM) fuel cells.

The EE33-T17 is ideal for test benches designed to measure the moisture content of the injected reaction gases (H2, O2) directly downstream of the humidifier. Due to its excellent measuring performance in the high humidity range (>85% RH), the sensor provides exact measured values, enabling optimum management of the moisture content.

Key Features

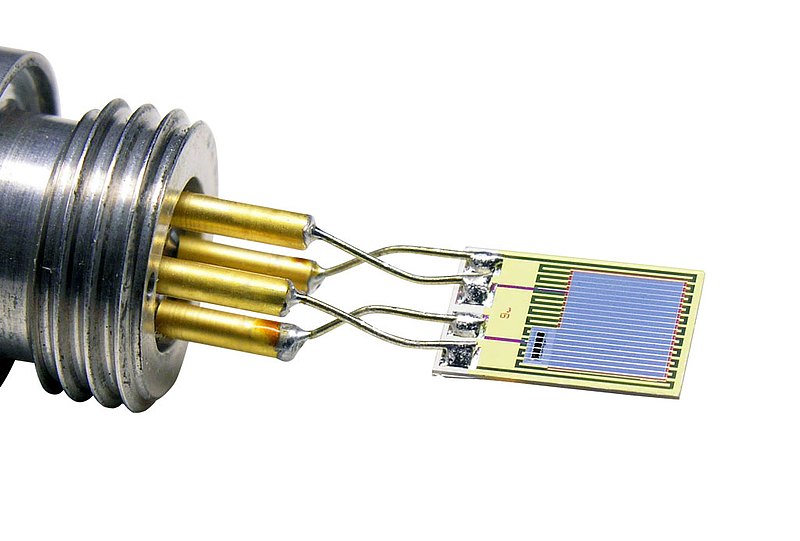

- Highest measurement accuracy with monolithic humidity sensor

- Heating modes for temporary condensation, permanent high humidity or chemical exposure

- Optional module for external triggering of heating mode

- Short response time and fast recovery after condensing conditions

- Precise measurement at permanent high humidity

- Outstanding temperature compensation

- Sensor protection against pollution and corrosion

- Rugged aluminium enclosure

- Pressure tight probe up to 100 bar

- Process temperature up to 180°C

- Analogue current and voltage outputs

- Optional RS-485 and standard RS-232 interface

- Optional alarm outputs

- Optional LCD Display

- Additional physical quantitites calculated

- Easy field adjustment

- Outputs freely configurable by user

- Dew point only type available

Technical data

- Measuring range

- 0...100% RH

-40...180°C (-40...356 °F) - Accuracy

- ±1.3% RH

±0.2 °C (0.36 °F) - Response time

- < 15s

- Serial interface

- RS232C + optional RS485

- Outputs

- 0-1/5/10 V or 0/4-20 mA

- Supply

- 24V AC/DC