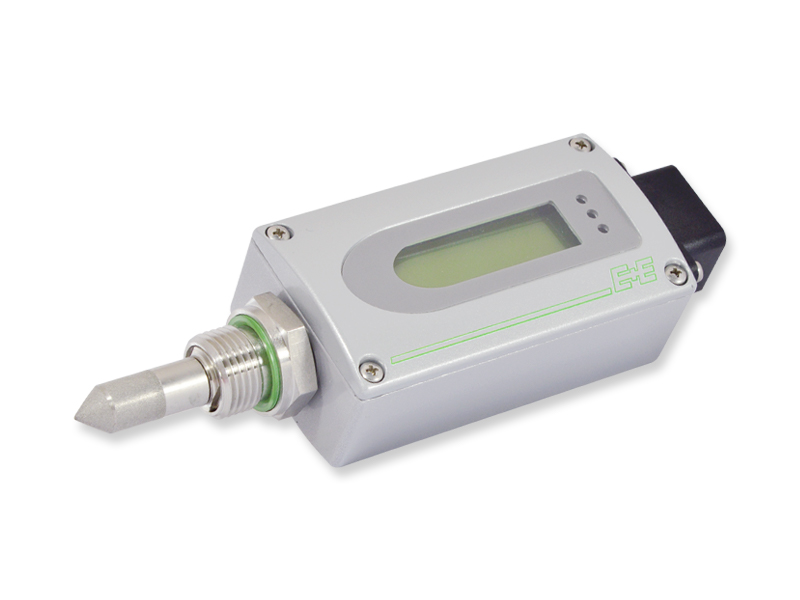

Miniature Dew Point Meter for Refrigeration Dryers

EE354

Reliable dew point monitoring is essential for minimizing ownership costs of compressed air supply with refrigeration dryers. It allows for condition based planning of the service intervals and for avoinding breakdowns.

The EE354 dew point meter is optimised for monitoring refrigeration dryers. The measurement accuracy of ±1 °C (±1.8 °F) over the range of -3...20 °C Td (26.6...68 °F Td) and excellent long-term stability of the dew point sensor make the EE354 the ideal meter for refrigeration dryers.

Due to its compact design, EE354 can be easily installed even in tight, confined spaces. The extremely rugged stainless steel enclosure with ½ ISO or NPT thread and the M12x1 electrical connection facilitate quick and easy integration into the measuring task.

Typical applications

- Compressed air networks

- Refrigeration dryer monitoring

EXTEND YOUR WARRANTY UP TO 5 YEARS WITH THE NEW

E+E CALIBRATION SERVICE PACKAGES

Our calibration service packages ensure that you are on the safe side when it comes to the accuracy and vailability of your measuring devices. Choose the right service package for your E+E product and benefit rom professional device service, calculable costs and excellent measuring accuracy in the long-term. Here you can find more detailed information.

Key Features

- Measurement range -20...50 °C Td (-4...122 °F Td)

- Measurement accuracy ±1 °C (±1.8 °F) at -3...20 °C Td (26.6...68 °F Td)

- Analogue output 4...20 mA

- MODBUS RTU digital interface

- Pressure-tight up to 80 bar (1160 psi)

Technical data

- Measurement range

- -20...50 °C (-4...122 °F) Td

- Accuracy

- ± 1 °C (± 1.8 °F) Td

- Outputs

- Modbus RTU and 4-20mA

- Power supply

- 10-28 V DC

Related products

Downloads EE354

FAQ

Yes. It is possible.

EE354 / EE355 are “Sigma Compatible Probes”, for details pleas see the Sigma 05 user manual.

For operations with the Sigma 05, the EE354 / EE355 requires manual setup (see Sigma 05 user manual) and a cable connection adapter.

The cable connection adapter can be realized with the accessories HA010819 and HA010706.

Accredited calibration certificate for dew point temperature is available upon request, please see our calibration website.