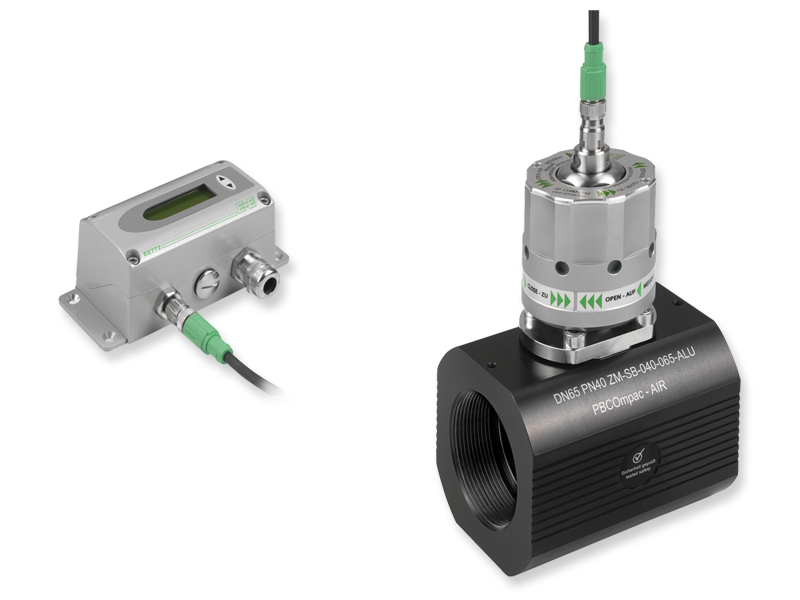

Flow Sensor for Compressed Air and Gases DN40 – DN80 / 40 bar

EE772

The EE772 is a multifunctional flow sensor compressed air and gases. Irrespective of pressure and temperature, the EE772 flow sensor registers mass flow, volumetric flow or standard flow.

The flow sensor can be used effectively to measure the consumption of compressed air, nitrogen, CO₂ or other non-corrosive gases.

The gauge mounting block allows for the installation and removal without flow interruption. Regular calibration, without taking into account the device downtime, is therefore always an option. Besides the mass flow probe, the gauge mounting block with hot tap valve can accomodate also a dew point and a pressure sensor.

EE772 flow sensor employs the well proven E+E hot-film sensor element with high immunity to contamination, which leads to outstanding long-term stability and accuracy even under harsh operating conditions.

With wide measuring range from 0.5 to 200 Nm/s (100...39370 SFPM) (1:400) and fast response time, one and the same flow meter model can be employed throughout the entire gas supply system. It records accurately even the smallest flow which represent an essential prerequisite for calculating consumption costs or for finding leaks.

Every E+E flow sensor undergoes a precise factory calibration procedure at a pressure of 7 bar (102 psi), the corresponding calibration certificate is included in the standard scope of supply. The EE772 flow sensor is available with an additional MODBUS RTU or M-BUS (Meter-Bus) interface.

Key Features

- Gauge mounting block with hot tap valve for rapid installation and removal without flow interruption

- Additional installation of dew point- and pressure sensor

- Remote, interchangeable probe for easy mounting

- Pipe diameter DN40 - DN80 (1 1/2" - 3")

- Pressure range up to 40 bar (580 psi) (PN40)

- wide measuring range up to 200 Nm/s (39370 SFPM)

- MODBUS RTU or M-BUS

Technical data

- Measured values

- standardized volumetric flow, mass flow, standardised flow, temperature, consumption

- Measuring range

- 0.5 - 200 Nm/s (100…39370 SFPM)

- Accuracy

- ±1.5 % of the measured value

- Pipe diameter

- DN40 up to DN80 (1 1/2" - 3")

- Outputs

- 0-10 V, 0/4-20 mA, Pulse, Switch, Modbus RTU or M-Bus

- Supply

- 18 - 30 V AC/DC