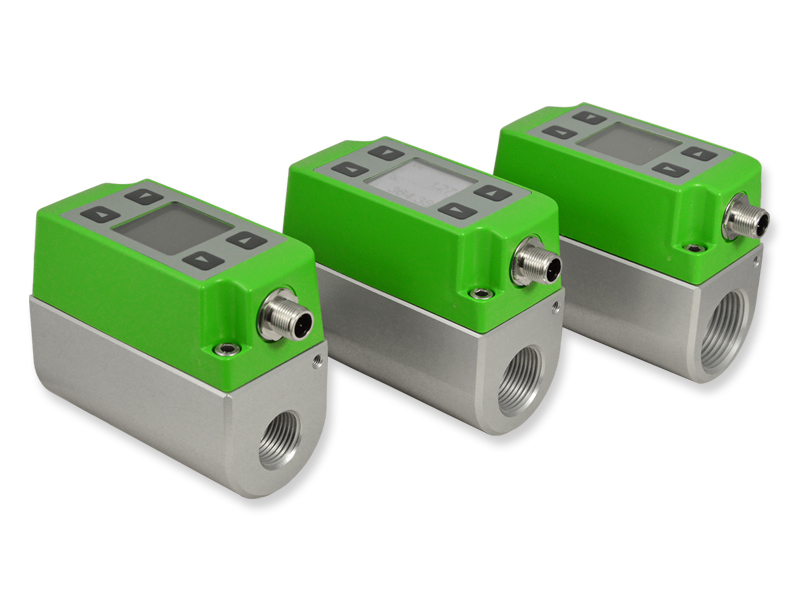

Modular, Compact In-line Flow Meter for DN15 to DN50

EE741

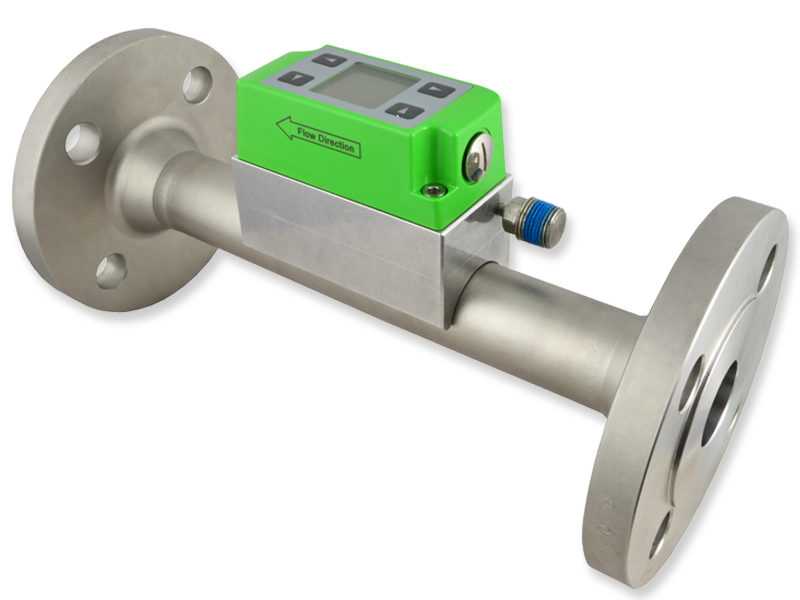

The EE741 in-line flow meter can be easily adapted for any measuring task. It is dedicated for accurate metering and monitoring of compressed air and technical gases in DN 15 to DN50 pipes.

The thermal measuring principle and the well proven E+E hot film sensor element lead to best long-term stability and fast response time.

Outstanding measuring accuracy, even in the lower measuring range, is achieved by an application-specific multi-point factory adjustment performed at 7 bar (102 psi). This allows reliable leak detection and corresponding energy savings. The construction of the EE741 flow meter is optimised for easy installation and maintenance.

Modular design

One and the same transmitter can be used for each of three pipe diameters:

- EE741: DN15 (1/2") / DN20 (3/4") / DN25 (1")

- EE741-N50: DN32 (1-1/4") / DN40 (1-1/2") / DN50 (2")

The pipe diameter is easily set via the display menu or the EE-PCS product configuration software.

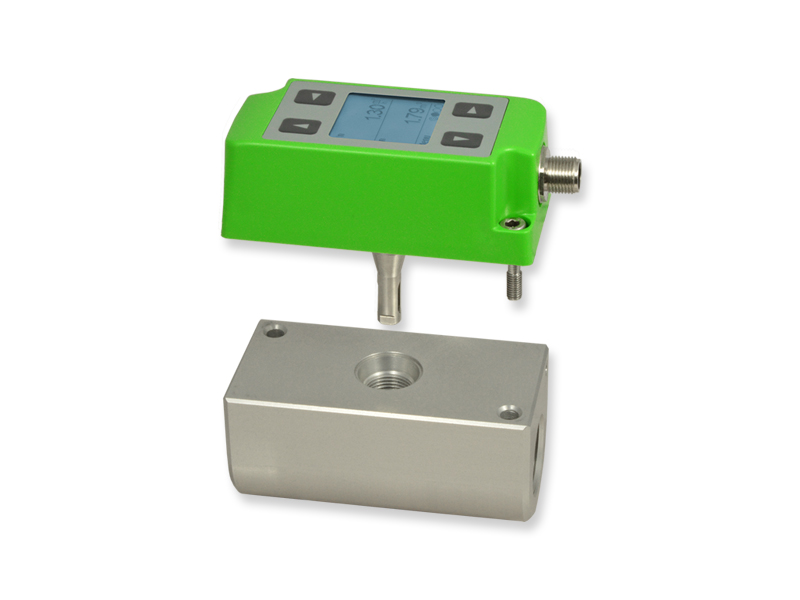

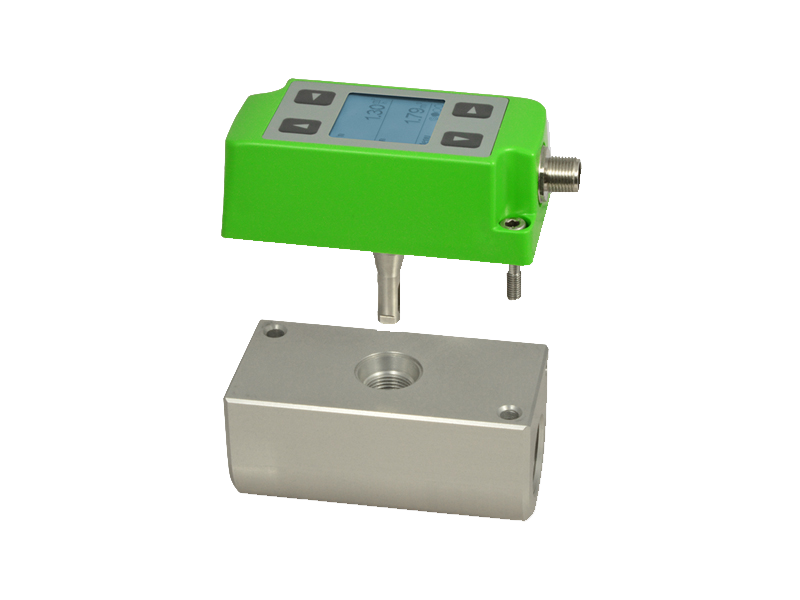

Once the gauge mounting block is installed in the pipeline, the transmitter can be installed and removed without any pipework. As a result, the EE741 flow meter is also ideal for temporary measurement at several installed mounting blocks. The sealing plug included in the scope of supply enable the normal operation of the compressed air system when the transmitter is removed.

Display (optional)

The state-of-the-art LCD shows the current measured values and the overall consumption. The EE741 setup can be easily performed with the push buttons and intuitive menu guidance. The display can be rotated in 90° increments with a push button for convenient orientation in any mounting position of the flow meter.

Typical Applications

- Compressed air consumption measurement

- Monitoring of technical gases O2, N2, Ar, CO₂. Other gases upon request

- Nitrogen generators

- Leak detection

For the use of this service, prior consent to the processing of your data and in particular to the setting of cookies is necessary. You can consent to the processing and setting of cookies here. Without your consent, your data will not be processed in connection with this service and no cookies will be set. You can revoke your consent at any time. For more information on cookies and the processing of your data in connection with this content and a way to revoke your consent, please see our privacy policy.

Key Features

- Modular design

- Removal without dissasembling the pipework

- Application-specific adjustment under pressure

- Exceptional price/performance ratio

- Analogue, pluse and switching output

- Modbus RTU and M-Bus

- Integrated consumption meter

Measurands

- Standard volume flow [Nm3/h, Nm3/min, l/min, l/s, SCFM]

- Mass flow [kg/h, kg/min]

- Standard flow [Nm/s, SFPM]

- Temperature [°C, °F]

- Integrated consumption meter (totalisator) for cost-effective consumption analysis without additional data logger

Technical data

- Measured values

- standardized volumetric flow, mass flow, standardised flow, temperature, consumption

- Pipe diameter

- DN15 / DN20 / DN25

DN32 / DN40 / DN50 - Measuring range - flow

- DN15: 0.2 - 76.3 Nm³/h (0.12 - 44.88 SCFM)

DN20: 0.4 - 135.6 Nm³/h (0.24 - 79.77 SCFM)

DN25: 0.6 - 212 Nm³/h (0.36 - 124.71 SCFM) - Measuring range - flow

- DN32: 0.9 - 347.4 Nm³/h (0.52 - 202.06 SCFM)

DN40: 1.4 - 542.8 Nm³/h (0.81 - 315.71 SCFM)

DN50: 2.2 - 848.2 Nm³/h (1.22 - 493.35 SCFM) - Accuracy - flow (*measured value)

- ±(3 % of mv* + 0.3% of full scale)

- Measuring range - temperature

- -20...60 °C (-4...140 °F)

- Accuracy - temperature

- ± 0.7 °C (1.26 °F)

- Outputs

- 0/4-20 mA, Pulse, Switch, Modbus RTU, M-Bus or IO-Link

- Supply

- 18 - 30 V DC