Air Flow Sensor for HVAC

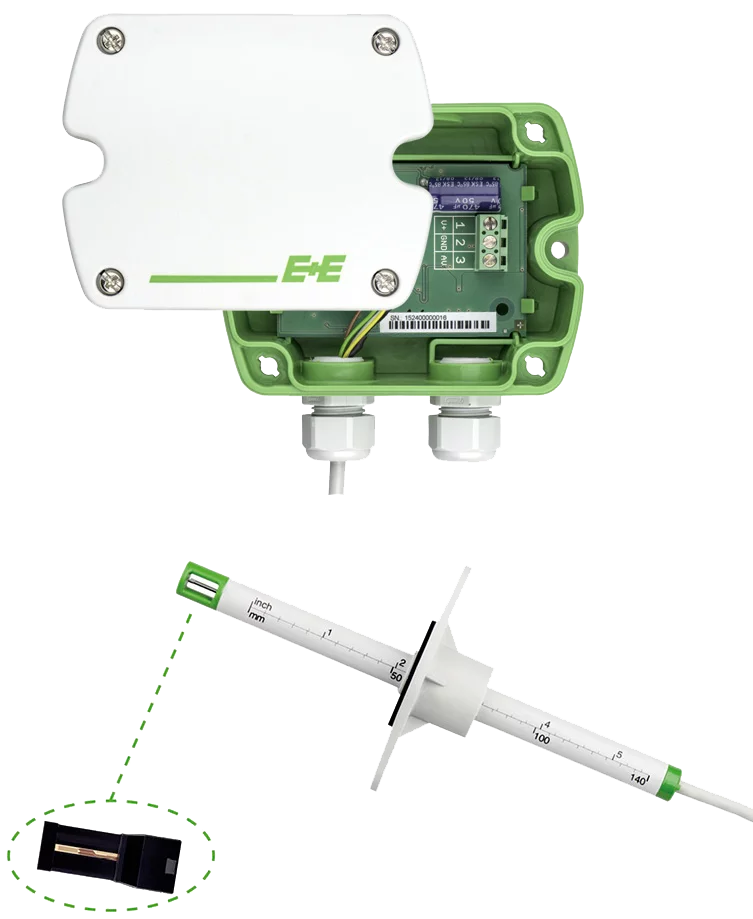

EE650

The EE650 air flow sensor is dedicated for accurate and reliable measurement in building automation and ventilation applications.

EE650 employs the new VTQ air flow sensor element, which operates on the thermal anemometer principle and is manufactured by E+E in state-of-the-art thin film technology.

Due to its innovative design, the VTQ air flow sensor element is very robust and highly insensitive to pollution, which leads to outstanding long-term performance.

The measured data is available either on an analogue voltage or current output, user selectable, or on the RS485 interface with Modbus RTU or BACnet MS/TP protocol.

The enclosure design and the mounting flange included in the scope of supply allow for easy installation or replacement. The configuration and adjustment of the EE650 can be comfortably performed on the electronics board or via digital interface.

Typical Applications

- HVAC

- Ventilation systems

- Process control

Key Features

- Best accuracy and long term stability

- High resistance to pollution and mechanical stress

- Measuring range 0.2 - 10/15/20 m/s (40 - 2000/3000/4000 ft/min), user selectable

- Current and voltage outputs, selectable

- RS485 interface with Modbus RTU or BACnet MS/TP

- Duct mount and remote probe versions

- Easy installation

- Digital interface for adjustment by user

Technical data

- Measuring range - user selectable

- 0...10 m/s (0...2000 ft/min)

0...15 m/s (0...3000 ft/min)

0...20 m/s (0...4000 ft/min) - Accuracy at 20 °C (68 °F), 45 % RH, 1013 hectopascal

- 0.2...10 m/s ±(0.2 m/s + 3 % of mv)

0.2...15 m/s ±(0.2 m/s + 3 % of mv)

0.2...20 m/s ±(0.2 m/s + 3 % of mv) - Response time - user selectable

- typ. 4 sec or typ. 1 sec.

- Output Analogue

- 0-10 V and 4-20 mA

- Output Digital

- Modbus RTU or BACnet MS/TP

- Supply

- 24 V AC/DC

Related products

Downloads EE650

FAQ

Transmitter with "two-wire" technology receive the power from the process, and the signal is carried on return wire (closed current loop). With "three-wires" technology the power supply is separate from current output: 2 wires are the power supply and the third carries the signal.