Dew Point Transmitters for Compressed Air Systems and Industrial Drying Processes

As industrial production processes become ever more demanding, the requirements for compressed air treatment and drying processes are also on the rise. Reliable dew point measurement and continuous monitoring of the dew point using a dew point transmitter is therefore crucial in ensuring that the entire production process runs smoothly and safeguarding a high level of product quality.

Dew Point Transmitters for Low Dew Points

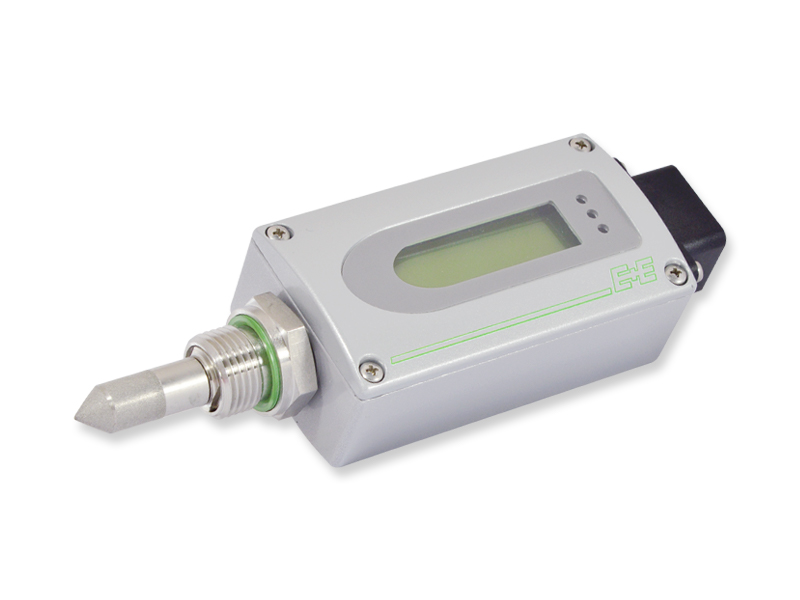

E+E dew point transmitters are suitable for installation in compressed air systems and pipelines with an operating pressure of up to 100 bar (1450 psi) and precisely measure the dew point temperature down to -60 °C Td (-76 °F Td).

As they are very small and highly accurate, E+E dew point transmitters are also ideal for OEM applications, for example for adsorption dryers, refrigeration dryers or plastic dryers.

- Smooth production processes thanks to dry compressed air.

- For compressed air systems, plastic dryers and industrial drying processes.

- Auto-calibration procedure for accurate measurement of very low dew point temperatures.