Compact Dew Point Sensor

EE371

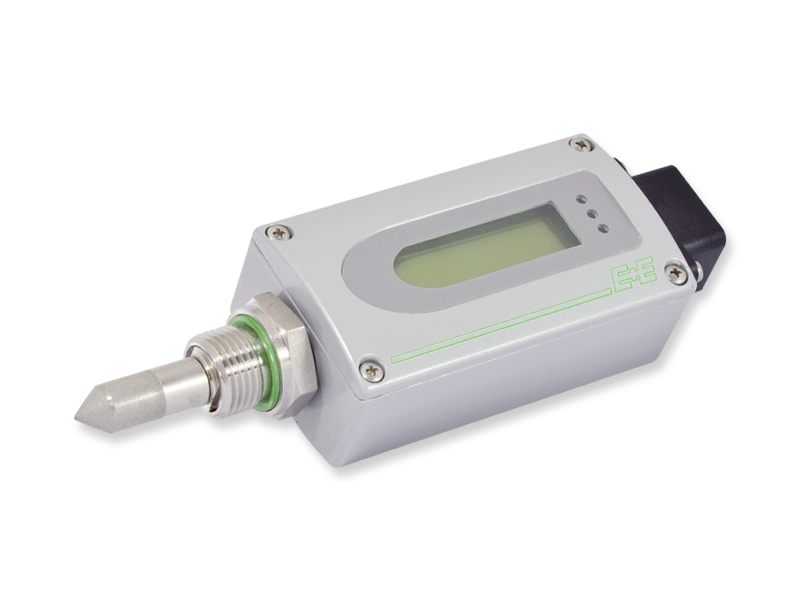

EE371 is dedicated for accurate and reliable monitoring of the dew point temperature (Td) in the range -60...60 °C Td (-76...140 °F Td), with pressure rating up to 100 bar (1 450 psi). It is ideal for compressed air systems and industrial process control. Besides Td, the device measures also frost point temperature (Tf) or volume concentration (Wv).

The EE371 features the innovative, monolithic E+E HMC01 humidity and temperature sensing element. In combination with a sophisticated auto-calibration procedure, this leads to accuracy better than ±2°C Td (±3.6 °F Td) and to excellent long term stability.

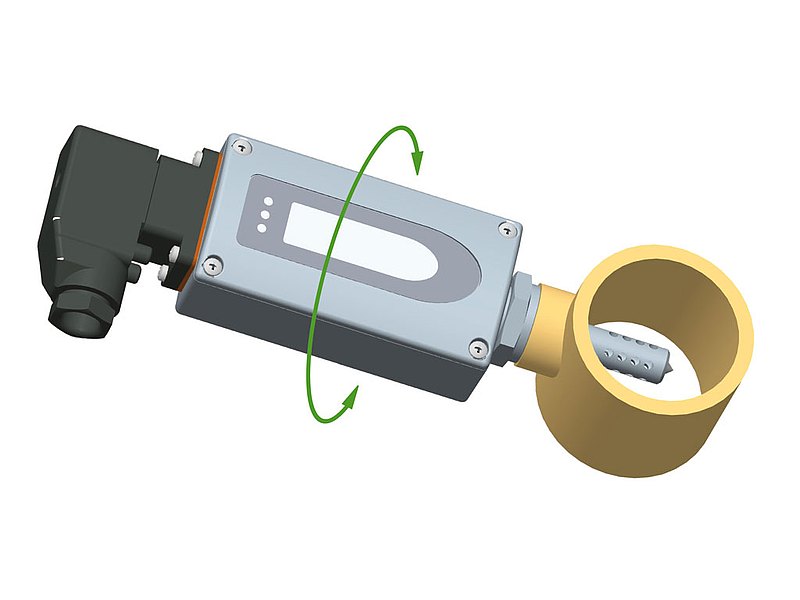

The robust metal enclosure, the swirling front-end, various process connections and sampling options allow for easy and comfortable design-in, mounting and operation. The measured data is available on two freely configurable voltage or current outputs as well as on the LCD display.

An optional adapter and the free EE-PCS Product Configuration Software facilitate easy configuration and adjustment of the EE371.

Key Features

- Accuracy ±2°C Td (±3.6 °F Td)

- Auto-calibration

- Pressure rating up to 100 bar (1450 psi)

- 360° swirling front-end

Technical data

- Measuring range

- -60...60 °C (-76...140 °F) Td

- Accuracy

- ±2 °C (±3.6 °F) Td

- Outputs

- 0-1/5/10 V or 0/4-20 mA

- Supply

- 15-30 V DC

Related products

Downloads EE371

FAQ

Low dew point means the difference between the ambient temperature and the dew point temperature is higher than 40 °C (104 °F). This corresponds to RH <5%.

The appropriate products are the EE371 and EE355. Both devices feature an auto-calibration procedure.

Auto-calibration is used by EE371 and EE355.

Accredited calibration certificate for dew point temperature is available upon request, please see our calibration website.